10.12.2025 | Sustainability

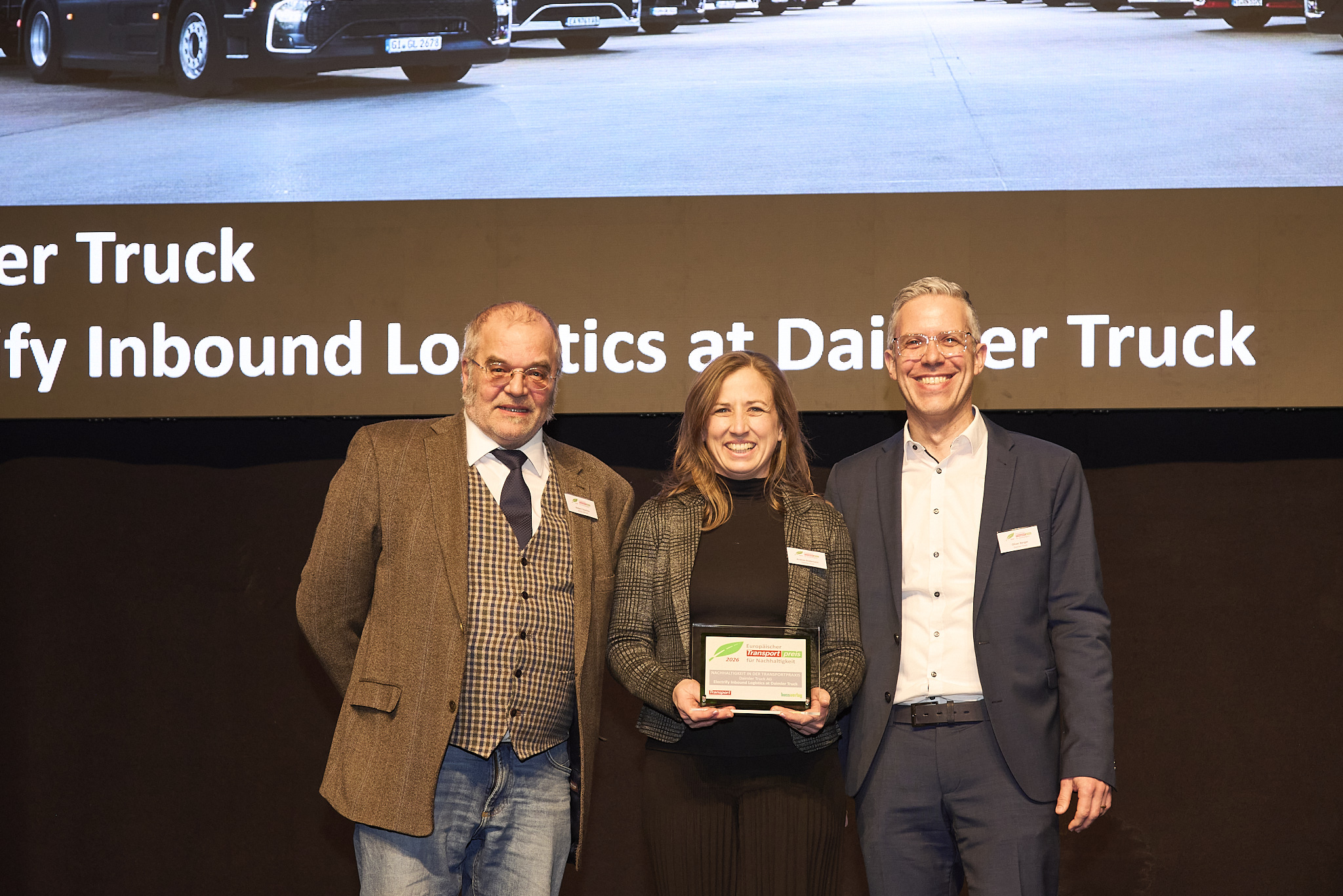

The project “Electrify Inbound Logistics” was honored end of November in Munich with the European Transport Award for Sustainability by Transport magazine, published by Huss-Verlag. Behind this achievement lies a clear goal: to gradually electrify inbound logistics traffic to the Wörth plant and the three component plants in Gaggenau, Mannheim, and Kassel. Marc Köster, who has been driving the project forward since its early days, accepted the award together with the project team. To understand what’s behind this success — and what personally motivates him — we sat down with Marc for a conversation.