A particularly small innovation: the Unimog Low

Download

A particularly small innovation: the Unimog Low

Leinfelden-Echterdingen – Mercedes-Benz Special Trucks is expanding its Unimog implement carrier portfolio and will be offering a vehicle with a particularly low loading height. In conjunction with the platform from Eggers Fahrzeugbau GmbH, the new Unimog U 219 Low has a loading sill height at the rear of less than 1.2 meters. This means that the loading height is around 20 centimeters lower than the previous loading height of…

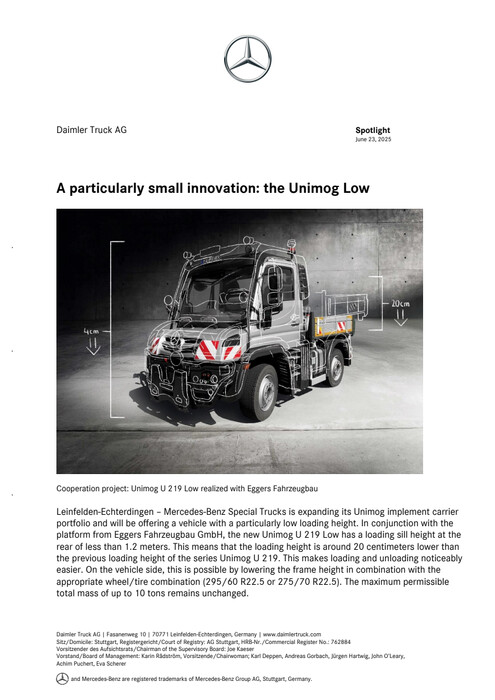

Leinfelden-Echterdingen – Mercedes-Benz Special Trucks is expanding its Unimog implement carrier portfolio and will be offering a vehicle with a particularly low loading height. In conjunction with the platform from Eggers Fahrzeugbau GmbH, the new Unimog U 219 Low has a loading sill height at the rear of less than 1.2 meters. This means that the loading height is around 20 centimeters lower than the previous loading height of the series Unimog U 219. This makes loading and unloading noticeably easier. On the vehicle side, this is possible by lowering the frame height in combination with the appropriate wheel/tire combination (295/60 R22.5 or 275/70 R22.5). The maximum permissible total mass of up to 10 tons remains unchanged.

The special platform from the partner, Eggers, is also crucial for the more ergonomic loading height. In the lowest version, the platform floor is only 14 centimeters above the top edge of the chassis frame. The platform is designed as a three-side tipper with an internal dimension of 2.22 meters long and 2.1 meters wide. The height of the side wall and the design of the front wall can be designed according to individual customer requirements.

The advantages of the Unimog Low concept pay off particularly in construction yards and for municipal work. Be it unloading equipment and material or loading gravel, earth or sand- every centimeter pays off at the end of the working day to support employees' ergonomic work.

The Unimog Low is equipped with the new UNI-TOUCH operating system. UNI-TOUCH makes handling implements more efficient and comfortable and supports intuitive operation of the vehicle. Using a touchscreen, users can make the appropriate settings for the respective task, assign individual functions to buttons or easily save and retrieve recurring processes. In addition, the optional multifunctional joystick can now be inserted into the preparation on the driver's seat or on the passenger seat, depending on the work situation. UNI-TOUCH is already installed in eight of the Unimog implement carriers on display at Demopark and can be experienced during live presentations.

Article assets

A particularly small innovation: the Unimog Low

New UNI-TOUCH operating system for Unimog implement carrier – intuitive, flexible, no fuss

New UNI-TOUCH operating system for Unimog implement carrier – intuitive, flexible, no fuss

New UNI-TOUCH operating system for Unimog implement carrier – intuitive, flexible, no fuss

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

A particularly small innovation: the Unimog Low

Lukas Hettmannsperger

Spokesperson Mercedes-Benz Special Trucks

lukas.hettmannsperger@daimlertruck.com

+49 170 3871112

Ulrike Burkhart

Spokesperson Mercedes-Benz Trucks Product, Service & eTruck

ulrike.burkhart@daimlertruck.com

+49 160 861 3757